Waste Water Management

A DAF (Dissolved Air Flotation) system is a wastewater treatment process that removes suspended solids, oils, and other contaminants from water by introducing fine bubbles of air or other gases.

In a DAF system, contaminated water is mixed with a coagulant or flocculant to aggregate the particles into larger clusters. Then, air is dissolved under pressure and released into the water, causing the particles to attach to the air bubbles and float to the surface as a froth or sludge layer. This layer is then mechanically skimmed off, removing the contaminants from the water.

DAF systems are commonly used in industries such as food processing, pulp and paper manufacturing, and wastewater treatment plants to remove pollutants before discharge into water bodies or further treatment processes. They are effective in treating high-load wastewater streams and can achieve high removal efficiencies for suspended solids, fats, oils, and greases.

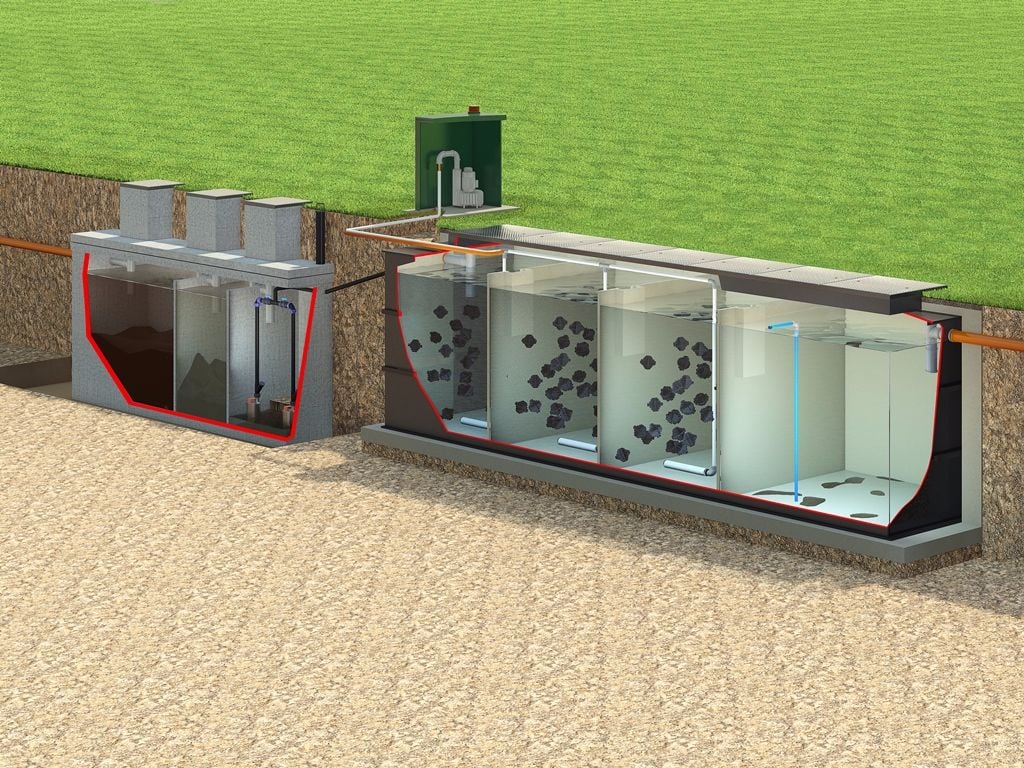

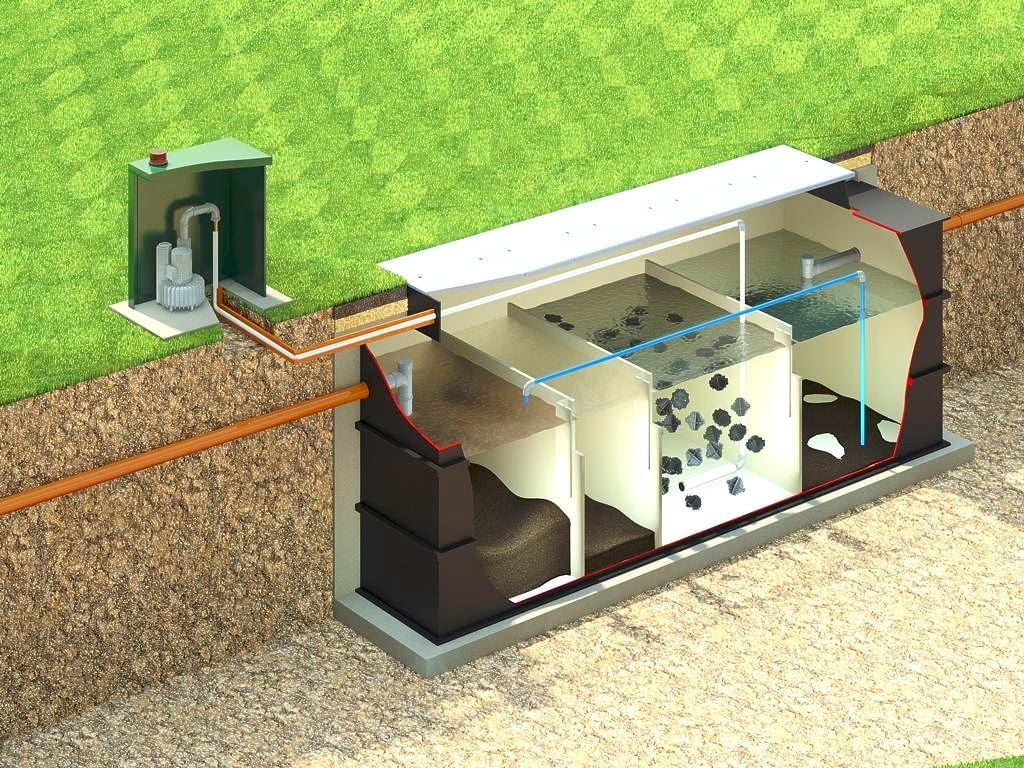

MBBR stands for Moving Bed Biofilm Reactor. It is a type of biological wastewater treatment process that utilizes a suspended media system to support the growth of microorganisms involved in the treatment of wastewater.

In an MBBR system, plastic media with a large surface area is suspended within a reactor or tank. Wastewater flows through the tank, and microorganisms attach themselves to the surface of the media, forming a biofilm. As the media moves freely within the tank, it provides agitation and mixing, ensuring contact between the wastewater and the biofilm for efficient treatment.

The microorganisms in the biofilm biologically degrade organic pollutants present in the wastewater, converting them into simpler and less harmful substances. MBBR systems are known for their high treatment efficiency, robustness, and flexibility in handling varying wastewater loads and compositions. They are commonly used in municipal wastewater treatment plants, industrial wastewater treatment facilities, and decentralized treatment systems.

A sludge treatment machine is a piece of equipment used in wastewater treatment plants to process and manage sludge, which is a semi-solid byproduct generated during the treatment of wastewater. These machines are designed to handle various aspects of sludge treatment, including thickening, dewatering, conditioning, and disposal.

There are several types of sludge treatment machines, each serving specific purposes:

- Sludge Thickening Machines: These machines are used to increase the concentration of solids in the sludge by removing water, reducing its volume for further processing.

- Sludge Dewatering Machines: Dewatering machines remove additional water from the sludge, further reducing its volume and producing a more solid material that is easier to handle and dispose of.

- Sludge Conditioning Machines: Conditioning machines are used to treat the sludge with chemicals or other agents to improve its dewaterability and reduce odor.

- Sludge Disposal Machines: These machines facilitate the disposal of treated sludge, which may involve incineration, landfilling, or reuse in agricultural or industrial applications.

Overall, sludge treatment machines play a crucial role in the proper management of sludge generated in wastewater treatment processes, ensuring compliance with environmental regulations and minimizing the environmental impact of sludge disposal.

SBR stands for Sequential Batch Reactor. It is a type of wastewater treatment process that operates in a batch mode, meaning that all treatment stages, including aeration, settling, and decanting, occur sequentially in the same tank or reactor.

In an SBR system, wastewater is introduced into the reactor during a filling phase. Once the reactor is filled, various treatment processes take place, such as biological treatment, where microorganisms degrade organic matter, and settling, where solids settle to the bottom of the reactor. The treated water is then decanted or discharged from the reactor.

After the treatment cycle is complete, the reactor undergoes a series of stages, including idle, settling, and decanting, before starting the next treatment cycle. This cyclic operation allows for flexible and efficient treatment of wastewater with varying flow rates and pollutant loads.

SBR systems are commonly used in both municipal and industrial wastewater treatment plants due to their versatility, ease of operation, and ability to achieve high treatment efficiencies.

Hydro Pure is able to provide MBR systems, as the one showed below:

STP stands for Sewage Treatment Plant. It is a facility designed to treat wastewater generated from domestic, commercial, and industrial sources to remove pollutants and contaminants before discharge into the environment or reuse.

The process of sewage treatment typically involves several stages:

- Preliminary Treatment: Large solids such as debris, grit, and other non-biodegradable materials are removed through physical processes like screening and grit removal.

- Primary Treatment: In this stage, suspended solids and organic matter are settled out of the wastewater through sedimentation or flotation processes, producing a sludge that can be further treated.

- Secondary Treatment: Biological processes are used to further degrade organic matter and remove dissolved contaminants. This can be achieved through methods such as activated sludge process, trickling filters, or sequencing batch reactors (SBRs).

- Tertiary Treatment: Additional treatment steps are applied to further polish the wastewater and remove specific contaminants like nutrients (nitrogen and phosphorus), pathogens, and trace pollutants. Tertiary treatment may include processes such as filtration, disinfection (e.g., chlorination or ultraviolet irradiation), and advanced oxidation.

- Sludge Treatment and Disposal: The sludge generated from primary and secondary treatment processes undergoes further treatment, such as thickening, dewatering, and digestion, to reduce its volume and stabilize its organic content. The treated sludge may be disposed of in landfills, incinerated, or beneficially reused as fertilizer or soil conditioner.

Overall, STPs play a critical role in protecting public health and the environment by treating wastewater to meet regulatory standards and minimizing the impacts of pollution on water bodies and ecosystems.

ETP stands for Effluent Treatment Plant. It is a facility designed to treat industrial wastewater before it is discharged into the environment or reused. ETPs are crucial for minimizing the environmental impact of industrial activities by removing pollutants and contaminants from wastewater.

The process of effluent treatment in an ETP typically involves several stages, similar to those in sewage treatment:

- Preliminary Treatment: Large solids, oil, and grease are removed from the wastewater through physical processes like screening, sedimentation, or filtration.

- Primary Treatment: In this stage, suspended solids and organic matter are further separated and settled out of the wastewater through sedimentation or flotation processes.

- Secondary Treatment: Biological processes are employed to further degrade organic pollutants and remove dissolved contaminants. This can include processes such as activated sludge, biological filters, or sequencing batch reactors (SBRs).

- Tertiary Treatment: Additional treatment steps are applied to further polish the wastewater and remove specific contaminants like nutrients, heavy metals, and other trace pollutants. Tertiary treatment may involve filtration, chemical precipitation, advanced oxidation, or membrane processes.

- Disinfection: The treated effluent may undergo disinfection using methods such as chlorination, ultraviolet (UV) irradiation, or ozonation to remove any remaining pathogens and ensure the water meets regulatory standards for discharge or reuse.

ETPs are tailored to the specific requirements of different industries and the characteristics of their wastewater streams. They play a crucial role in preventing pollution, protecting water resources, and ensuring compliance with environmental regulations.

CPI stands for Corrugated Plate Interceptor, a type of water treatment device used primarily for the separation and removal of oil and solids from wastewater streams.

The CPI operates on the principle of gravity separation. It consists of a series of parallel corrugated plates, typically inclined at an angle, which provide a large surface area for the oil and solids to accumulate. As the wastewater flows through the CPI unit, the corrugated plates create a laminar flow pattern, allowing lighter oil droplets to rise to the surface and heavier solids to settle to the bottom.

Once separated, the oil and solids are collected and removed from the CPI unit, while the clarified water exits through an outlet. CPI units are commonly used in industrial applications, such as oil refineries, petrochemical plants, and wastewater treatment facilities, where the removal of oil and solids is essential for environmental compliance and process efficiency.

Hydro Pure is able to provide MBBR Water Treatment system, with polyethylene and the sizes range from 2m3 to 300m3:

Hydro Pure is able to provide carton printing waste water treatment equipment: